在高精密涂布和更广泛领域成为世界级头部企业。

-

About SPS

About SPS

SPS was founded by a famous polymer chemist, Dr. Jinshan Wang, who served as the chairman of the board of directors. In just eight years, SPS has grown from a tiny startup transformed into a leading enterprise in slot die precision technology, and now operating three subsidiaries, namely SPS Shanghai, SPS Suzhou. SPS Yangzhou.

SPS was founded by a famous polymer chemist, Dr. Jinshan Wang, who served as the chairman of the board of directors. In just eight years, SPS has grown from a tiny startup transformed into a leading enterprise in slot die precision technology, and now operating three subsidiaries, namely SPS Shanghai, SPS Suzhou. SPS Yangzhou. -

Products

Products

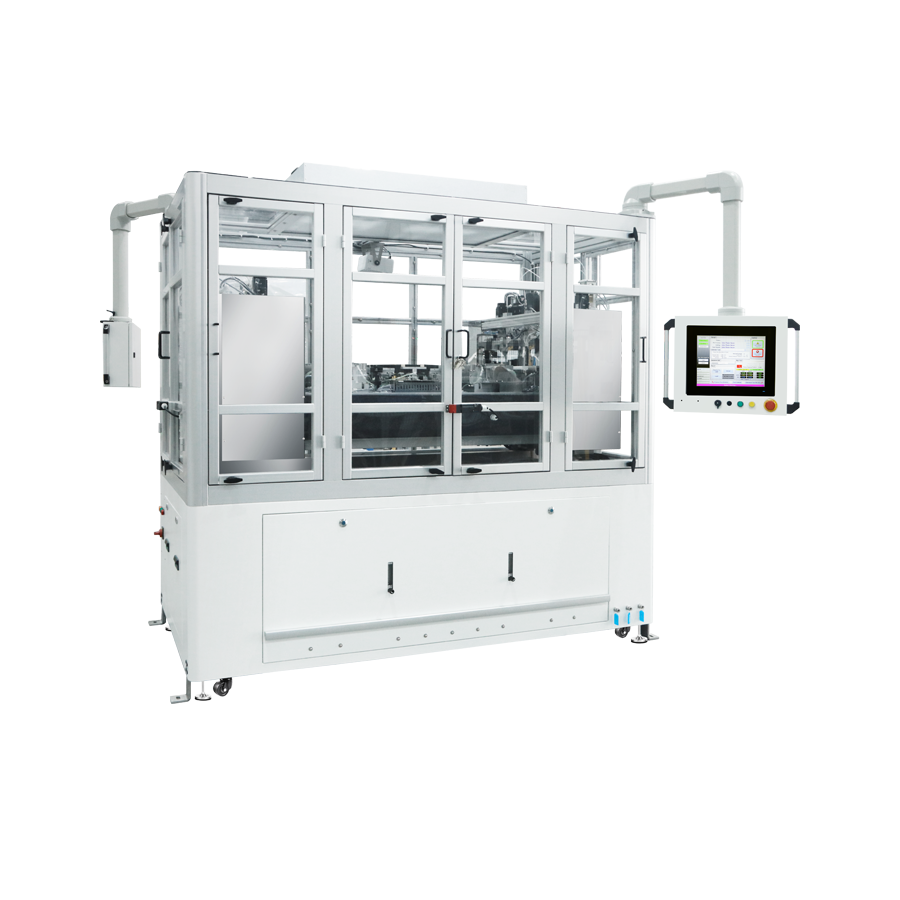

SPS focuses on the design, development and manufacturing of precision solution film-forming slit coating + vacuum dry baking equipment and its core components, and is the world's leading enterprise in the field of precision solution film-forming equipment in China.

SPS focuses on the design, development and manufacturing of precision solution film-forming slit coating + vacuum dry baking equipment and its core components, and is the world's leading enterprise in the field of precision solution film-forming equipment in China. -

SPRI

SPRI

SPS focuses on three-piece coating, and at the same time builds a public platform for perovskite research institutes SPRI, which has the functions of proofing, technology development and talent training to promote the rapid development of the industry. The institute plays a key role in the industrialization process and is a process accelerator and industrial amplifier.

SPS focuses on three-piece coating, and at the same time builds a public platform for perovskite research institutes SPRI, which has the functions of proofing, technology development and talent training to promote the rapid development of the industry. The institute plays a key role in the industrialization process and is a process accelerator and industrial amplifier.

-

Services

Services

At SPS, we understand the importance of customer service. We are committed to providing customers with a professional, efficient and satisfaction-oriented service experience. Whether it is product consultation, technical support or after-sales service, we will go all out to ensure that every customer can feel our intentions and professionalism. SPS firmly believes that excellent customer service is the cornerstone of sustainable development of enterprises, and it is also the key to winning the trust and loyalty of customers.

At SPS, we understand the importance of customer service. We are committed to providing customers with a professional, efficient and satisfaction-oriented service experience. Whether it is product consultation, technical support or after-sales service, we will go all out to ensure that every customer can feel our intentions and professionalism. SPS firmly believes that excellent customer service is the cornerstone of sustainable development of enterprises, and it is also the key to winning the trust and loyalty of customers. -

Contact Us

Contact Us

Whether you have any questions, needs, or suggestions, we look forward to getting in touch with you. Through the "Contact Us" channel, you can easily communicate with us, and we will be happy to provide you with the most timely and professional response. We value every opportunity to communicate with you and believe that through close cooperation between the two sides, we can create a better future together.

Whether you have any questions, needs, or suggestions, we look forward to getting in touch with you. Through the "Contact Us" channel, you can easily communicate with us, and we will be happy to provide you with the most timely and professional response. We value every opportunity to communicate with you and believe that through close cooperation between the two sides, we can create a better future together. -

News

News

SPS "Dynamic Information" column is committed to providing you with the latest tech developments, market trends, industry news and other important information. By surfing our latest news, you will be able to understand our latest achievements, strategic planning and future prospects, and witness the growth and transformation of SPS.

SPS "Dynamic Information" column is committed to providing you with the latest tech developments, market trends, industry news and other important information. By surfing our latest news, you will be able to understand our latest achievements, strategic planning and future prospects, and witness the growth and transformation of SPS.